Understanding Laminating Resin

Laminating resin is a critical material in the fields of construction, manufacturing, and craftsmanship. It serves as a versatile adhesive that bonds various materials while providing structural integrity to composites. This article dives deep into the intricacies of laminating resin, including its types, applications, best practices for application, common challenges, and methods to measure project success. To explore more about laminating resin, feel free to visit laminating resin.

What is Laminating Resin?

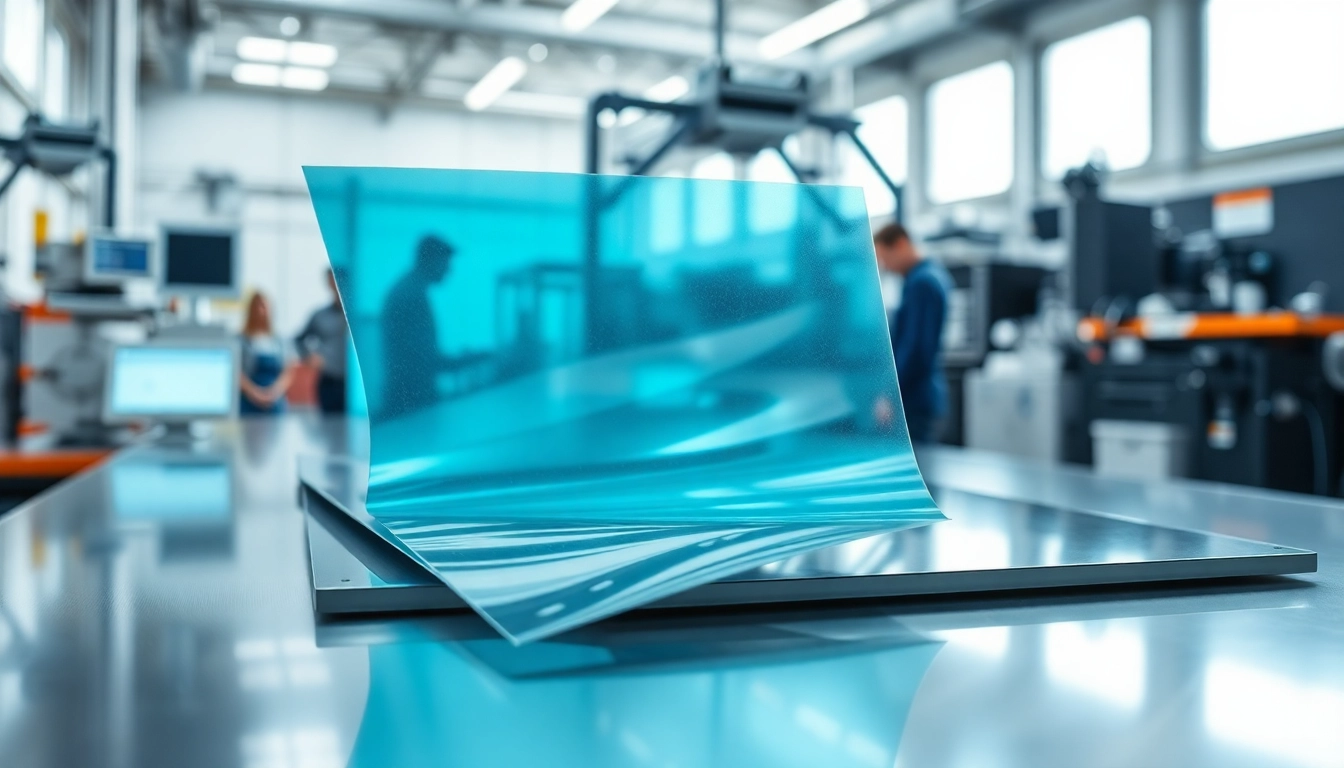

Laminating resin is a specialized polymer resin, typically used to create a strong adhesion between layers of materials, particularly in layering processes involving fiberglass and other composite materials. Primarily, there are two types of laminating resins: polyester and epoxy. These resins react through a chemical curing process, which solidifies them into a robust, durable matrix.

Polymers used in laminating resins can be categorized based on their chemical composition, performance characteristics, and application methods. Understanding the differences between these types is crucial for selecting the right resin for a specific project.

Types of Laminating Resin

1. Polyester Resin: This is one of the most widely used laminating resins, particularly in marine and automotive applications. It is known for its quick curing times and excellent surface adhesion. Polyester resin is often used when cost is a factor and when weight is a consideration.

2. Epoxy Resin: Known for its superior strength and flexibility, epoxy laminating resin is ideal for applications requiring high structural integrity. It has better adhesion properties and is less prone to cracking compared to polyester resin. Epoxy resins also offer enhanced resistance to chemicals and environmental stress.

3. Vinyl Ester Resin: This hybrid offers attributes of both polyester and epoxy resins. It provides robust resistance to water absorption, making it suitable for marine environments. Vinyl ester resin is typically used in critical applications that demand high performance and durability.

Benefits of Using Laminating Resin

Implementing laminating resin in projects offers numerous benefits:

- Durability: Laminating resins enhance the long-term durability of the structure, resisting environmental stressors and maintaining integrity over time.

- Weight-to-Strength Ratio: The lightweight nature of laminating resin composites is ideal for applications where weight savings are critical, such as in aerospace and automotive industries.

- Customizability: Laminating resins can be formulated to meet specific performance requirements, such as flexibility, adhesion, or thermal resistance.

- Aesthetic Appeal: Laminated surfaces can offer a sleek, smooth finish, enhancing the product’s visual appeal.

- Cost-Effectiveness: Utilizing laminating resin can lead to lower production costs by reducing material and labor requirements while increasing the longevity of the final product.

Applications of Laminating Resin

Laminating resins are used across various industries, demonstrating their versatility and efficacy in multiple applications. In this section, we explore some of these applications and how they optimize processes and enhance product quality.

Laminating Resin in Marine Construction

The marine industry is one of the largest consumers of laminating resins, particularly polyester and vinyl ester variants. Laminating resins are essential for creating lightweight and strong boat hulls, decks, and superstructures. They provide excellent adhesion to fiberglass fabrics, ensuring that the components maintain structural integrity against water pressure and environmental conditions.

Furthermore, laminating resin can help ensure vessels have a long lifespan, requiring minimal maintenance. The ability to bond with various materials makes laminating resin an integral part of modern marine construction.

Laminating Resin for Composite Materials

In advanced manufacturing processes, laminating resin plays a significant role in the production of composite materials used in construction, automotive, and aerospace industries. By accurately applying laminating resins to composite layers, manufacturers can create products with superior mechanical properties, reducing weight while enhancing structural efficiency.

Laminating resin applications can include the fabrication of components such as airplane wings, automotive body parts, and wind turbine blades, where the performance and durability of the final product are paramount.

Laminating Resin in Arts and Crafts

Beyond industrial applications, laminating resin has found a significant following in arts and crafts. Artists and crafters utilize laminating resin for encapsulating items, creating custom furniture, and making intricate art pieces. The ability of laminating resin to provide a glossy, protective finish while preserving the details of embedded objects makes it a favorite among creative individuals.

Moreover, the resin comes in various formulations that allow crafters to choose options that cure clear or colored, effectively expanding the artist’s palette for projects.

Best Practices for Applying Laminating Resin

To achieve optimal results when working with laminating resin, following best practices during application is crucial. This section outlines effective techniques for surface preparation, application, and finishing processes.

Surface Preparation Techniques

Proper surface preparation is vital to ensure that bonding adheres effectively. Here are a few steps to ensure ideal conditions for application:

- Cleaning: Ensure surfaces are free of dust, grease, and contaminants. Use appropriate cleaners based on the material type.

- Sanding: Sanding surfaces roughens them, allowing better adhesion for the laminating resin. Use progressively finer sandpaper to prepare the surface adequately.

- Priming: In some applications, a primer may enhance adhesion between layers, especially when dealing with various substrates.

Application Methods for Laminating Resin

Once the surface is prepared, selecting the right application method is crucial. Common methods include:

- Brush Application: Ideal for small projects or precise tasks. A brush allows you to manipulate the resin accurately on the surface.

- Squeegee Method: For large surfaces, a squeegee can help spread the laminating resin evenly, ensuring complete coverage.

- Vacuum Infusion: This advanced technique allows for thorough saturation of materials and is often used in composite manufacturing. It minimizes air pockets that could weaken the final structure.

Techniques for Smooth Finishes

Achieving a smooth finish with laminating resin can enhance aesthetic appeal and improve performance. Here are some techniques to consider:

- Layering: Applying multiple thin layers in succession can yield smoother results than one thick coat. Each layer should be allowed to cure properly before adding the next.

- Using Wax or Release Agents: Applying a wax or a release agent can improve the surface finish and make the final product easier to demold.

- Post-Cure Finishing: After the initial cure, sanding and polishing can refine the surface, presenting an immaculate finish for visible surfaces.

Common Challenges When Using Laminating Resin

Even experienced users of laminating resin encounter challenges during application. Understanding potential pitfalls can lead to effective solutions to maintain project quality. This section examines common issues and how to address them.

Identifying Cure Issues

Cure issues may arise due to incorrect mixing, environmental factors, or using expired materials. Signs of improper curing include sticky surfaces, cloudy finishes, or weak bonds. Here are suggestions for prevention and remediation:

- Always check the resin’s expiration date before use.

- Follow the manufacturer’s mixing ratios accurately.

- Monitor environmental conditions such as temperature and humidity, as these can significantly affect curing times.

Dealing with Bubbles and Imperfections

Bubbles in the resin can result from improper mixing or environmental fluctuations. To mitigate this problem:

- Mix gently to minimize air incorporation.

- Consider using a vacuum chamber to remove air from the mixture before application.

- After application, gently heat the surface with a heat gun to draw bubbles to the surface for removal.

Understanding Environmental Factors

Environmental factors can play a significant role in the success of laminating resin applications.

Humidity and temperature can both impact drying times and the final quality of the finish. Ideally, resin should be applied in controlled environments, ideally between 70°F and 85°F with low humidity levels. If working in less-than-ideal conditions:

- Employ heating devices to maintain temperature.

- Monitor humidity levels, if possible, and use dehumidifiers if required.

Measuring Success with Laminating Resin Projects

Once projects have been completed, measuring their success is essential for continuous improvement. This section outlines various performance metrics and evaluation methods.

EVALUATING the Quality of Laminated Surfaces

Quality evaluation involves assessing both visual and structural aspects of the laminated surfaces:

- Visual Inspection: Check for uniformity in thickness, color clarity, and the absence of imperfections.

- Physical Testing: Perform adhesion tests by conducting stress tests that measure the bond strength of the laminated structure.

Performance Metrics for Laminating Resin Applications

Performance can be assessed by considering factors such as:

- Durability: Evaluate how the laminated products perform under real-world conditions such as exposure to moisture, heat, or mechanical stress.

- Maintenance Requirements: Track how often the laminated surfaces require maintenance or repairs over time.

- User Feedback: Collect insights from end-users about their experiences with the laminated products to identify strengths and areas for improvement.

Feedback and Improvement Strategies

To optimize the use of laminating resin, maintaining open lines of communication with project stakeholders is essential. Feedback can provide valuable insights for future projects. Strategies for collecting actionable feedback include:

- Surveys: Distribute satisfaction surveys after project completion.

- Regular Meetings: Hold debriefings with the team and stakeholders to discuss what worked and what did not.

- Documentation: Keep thorough records of project specifics and outcomes, allowing for retrospective evaluations and strategic planning for subsequent projects.