Understanding Soft Capsule Encapsulation Machines

What Are Soft Capsule Encapsulation Machines?

Soft Capsule Encapsulation Machines are specialized equipment used in the pharmaceutical and nutraceutical industries for producing soft gelatin capsules. These machines facilitate the encapsulation process, enabling the precise filling of liquid formulations into soft capsules made from gelatin or other polymers. The efficiency and automation of these machines have revolutionized the way products are manufactured, ensuring higher accuracy, consistency, and quality in capsule production.

Benefits of Using Soft Capsule Encapsulation Machines

The use of Soft Capsule Encapsulation Machines offers numerous advantages:

- Precision: These machines provide accurate measurements of ingredients, ensuring each capsule contains the exact dosage required.

- Flexibility: They can accommodate various formulations, including oils, extracts, and powders, allowing manufacturers to diversify their product lines.

- Improved Bioavailability: The gelatin capsules often enhance the bioavailability of the active ingredients, improving absorption in the body.

- Reduced Labor Costs: Automation reduces the need for extensive manual labor, leading to cost savings in production.

- Quality Control: Advanced technologies enable real-time monitoring of production parameters, helping maintain high-quality standards.

Incorporating Soft Capsule Encapsulation Machines into the manufacturing process can significantly enhance productivity and product quality.

Key Features to Look for in Soft Capsule Encapsulation Machines

When selecting a Soft Capsule Encapsulation Machine, consider the following essential features:

- Production Capacity: Choose a machine that matches your production requirements, whether small, medium, or large scale.

- Automation Level: Opt for machines with higher automation capabilities to minimize manual interventions.

- Ease of Cleaning: Select machines that are designed for easy disassembly and cleaning to ensure compliance with hygiene standards.

- Compatibility: Ensure the machine can handle various types of formulations and capsule sizes.

- Technical Support: Prioritize manufacturers that offer robust technical support and training for machine operation.

Types of Soft Capsule Encapsulation Machines

Different Technologies in Soft Capsule Encapsulation Machines

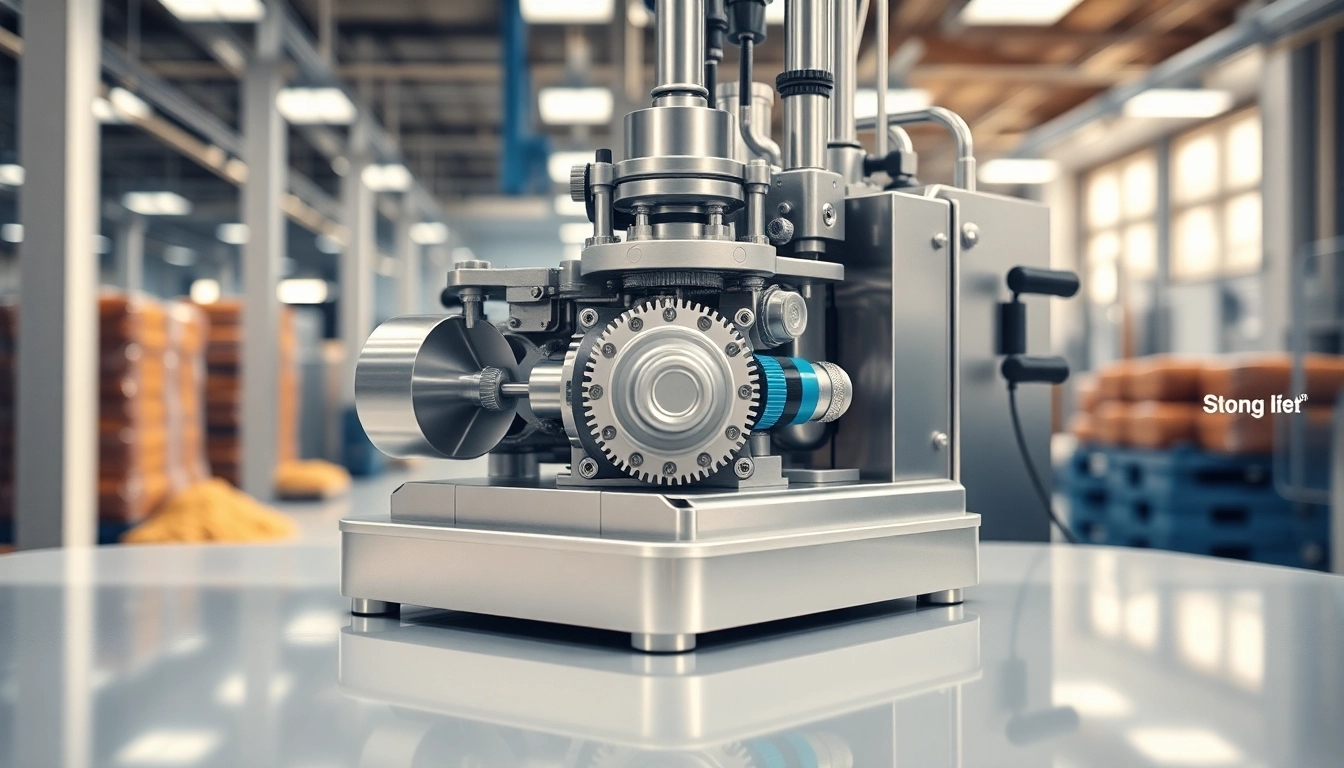

Soft Capsule Encapsulation Machines utilize different technologies categorized primarily into rotary die and reciprocating die systems. The rotary die method is the most common, featuring continuous movement and high-speed production. It incorporates a pair of rotary dies that mold and cut the capsules as the gelatin film moves through the system.

On the other hand, the reciprocating die method is suitable for smaller production volumes. This technology operates cyclically, with capsules formed in batches, making it more viable for R&D purposes or specialized production needs.

Vertical vs. Horizontal Soft Capsule Encapsulation Machines

Soft Capsule Encapsulation Machines can also be classified based on their configuration: vertical and horizontal. Vertical machines typically occupy less floor space and are easier to operate for small to medium-scale production. They work well for products with thinner liquid formulations and are generally easier to clean.

Conversely, horizontal machines tend to have larger production capacities and are geared towards larger manufacturing operations. They can handle a wider range of liquids and offer advantages in terms of scalability.

Choosing the Right Type of Soft Capsule Encapsulation Machines

Choosing the right type of Soft Capsule Encapsulation Machine depends on several factors, such as:

- Production Volume: Assess your production needs to determine whether you require a smaller, specialized machine or a high-capacity system.

- Formulation Characteristics: Consider the viscosity, temperature sensitivity, and stability of your formulations when deciding on machine type.

- Space Constraints: Account for the available floor space in your facility to select a machine configuration that fits your environment.

- Budget: Establish a budget that aligns with your operational needs while factoring in long-term value and return on investment.

Operational Aspects of Soft Capsule Encapsulation Machines

Setup and Calibration of Soft Capsule Encapsulation Machines

The setup and calibration of Soft Capsule Encapsulation Machines are crucial for optimal performance. Proper calibration ensures that the machine operates within the specified parameters, leading to consistent product quality. This process typically involves adjusting factors such as temperature, humidity, and machine speed according to the specific requirements of the gelatin and formulation being used.

It’s important to follow the manufacturer’s guidelines and conduct regular testing of the machine’s output to maintain calibration over time. This may include checking the weight and integrity of the capsules and making necessary adjustments to the machine settings as needed.

Common Operational Issues and Solutions

Operational issues can arise during the use of Soft Capsule Encapsulation Machines, including:

- Jamming: This often occurs due to incorrect setup or improper formulation viscosity. To address it, ensure that the machine is correctly calibrated and that the formulation meets the necessary specifications.

- Quality Control Failures: Inconsistent capsule fill weights or leaks may indicate issues with the machine or formulation. Regular maintenance and thorough testing can help alleviate these problems.

- Equipment Malfunctions: Mechanical failures can disrupt production. Establish a preventive maintenance schedule to identify and address potential issues before they escalate.

Maintenance Best Practices for Soft Capsule Encapsulation Machines

Maintaining Soft Capsule Encapsulation Machines is essential for ensuring longevity and optimal performance. Best practices include:

- Regular Cleaning: Clean the machine after every production run to prevent residue buildup and contamination.

- Scheduled Servicing: Implement a maintenance schedule that adheres to the manufacturer’s recommendations for servicing and inspections.

- Monitoring Performance: Keep track of the machine’s output and performance metrics to identify any deviations that may indicate wear and tear.

- Training Operators: Ensure that all operators are well-trained in both the operation and maintenance of the machine to minimize human error and enhance safety.

Performance Metrics for Soft Capsule Encapsulation Machines

Key Performance Indicators to Monitor

Monitoring the right performance metrics is vital for quality control and operational efficiency in soft capsule production. Key performance indicators (KPIs) include:

- Output Rate: Measure the number of capsules produced within a specific time frame to assess machine efficiency.

- Fill Weight Variability: Monitor the consistency of capsule fill weights to ensure accuracy and adherence to product specifications.

- Downtime: Track any downtime due to maintenance or errors, which can impact overall productivity.

- Batch Quality: Assess the quality of each production batch through inspections and testing to maintain regulatory compliance.

Comparing Efficiency of Different Soft Capsule Encapsulation Machines

When comparing the efficiency of various Soft Capsule Encapsulation Machines, consider factors such as:

- Speed: Evaluate the maximum production rates each machine can achieve, as higher speeds often translate to increased output.

- Adaptability: Review how well each machine accommodates different formulations and capsule sizes without requiring extensive changes to settings.

- Energy Consumption: Assess the energy requirements of each machine, as energy-efficient models can lead to significant cost savings in the long run.

- Operational Costs: Analyze the total cost of ownership, including initial investment, maintenance costs, and labor requirements.

Improving Output Quality with Soft Capsule Encapsulation Machines

Improving the quality of output from Soft Capsule Encapsulation Machines involves several strategies:

- Optimizing Formulations: Conduct thorough formulation testing to identify the optimal combinations of active ingredients and excipients.

- Utilizing Advanced Technology: Invest in machines equipped with the latest technologies for monitoring and control to enhance production quality.

- Implementing Quality Control Measures: Establish standardized protocols for testing and validating the quality of capsules at various stages of production.

- Operator Training: Ensure operators are well-trained in quality assurance practices, enhancing their ability to identify and rectify potential issues.

The Future of Soft Capsule Encapsulation Technology

Emerging Trends in Soft Capsule Encapsulation Machines

The future of Soft Capsule Encapsulation Machines is being shaped by several emerging trends:

- Increased Automation: Automation technologies, including robotics and AI, are being integrated into encapsulation processes to streamline operations.

- Personalized Medicine: A growing demand for personalized health solutions is pushing manufacturers to adopt flexible machines capable of producing customized capsules.

- Sustainability: Manufacturers are exploring the use of environmentally friendly materials and processes, aligning with global sustainability goals.

- Smart Manufacturing: The adoption of IoT and data analytics in production processes is facilitating better real-time monitoring and efficiency improvements.

Impact of Automation on Soft Capsule Encapsulation Machines

Automation is significantly impacting the operation of Soft Capsule Encapsulation Machines by:

- Enhancing Production Efficiency: Automated machines can operate continuously without the need for frequent manual interventions, increasing throughput.

- Improving Precision: Automation reduces the potential for human error, leading to more accurate and consistent capsule production.

- Facilitating Data Collection: Automated systems can generate extensive data on production metrics, enabling more effective quality control and analysis.

- Reducing Labor Costs: By minimizing the need for manual oversight, automation can lead to considerable labor savings over time.

Predictions for the Evolution of Soft Capsule Encapsulation Machines

The evolution of Soft Capsule Encapsulation Machines is expected to follow several trajectories, including:

- Increased Integration of Technology: Future machines will likely feature even more advanced technologies such as machine learning for predictive maintenance and real-time optimization.

- A Greater Focus on Customization: As demand for personalized formulations increases, machines will need to adapt more easily to a variety of capsule specifications.

- Sustainability Innovations: There will be a continued emphasis on developing greener encapsulation processes and materials that align with consumer preferences for eco-friendly products.

- Enhanced User Experience: Future designs will likely prioritize user-friendliness, with better interfaces and support systems for operators and maintenance personnel.