Understanding Metal Stamping Dies

What are Metal Stamping Dies?

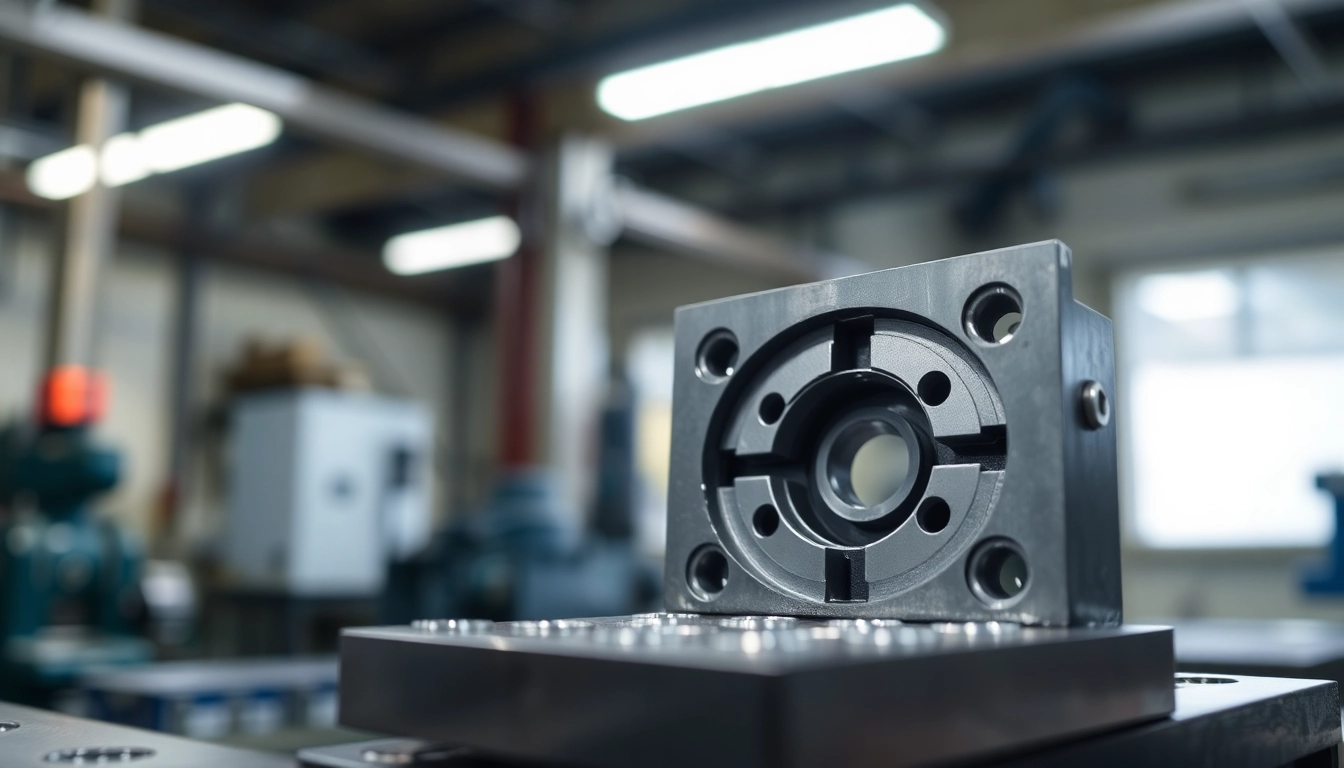

Metal stamping dies are specialized tools used to shape and cut various materials, predominantly metal, into specific forms and dimensions. These dies operate through a pressing process, where raw material is manipulated to create components for numerous applications. Their design is fundamental in machining and manufacturing environments, where precision and accuracy are paramount. Engineered from high-quality tool steel, Metal Stamping Dies provide exceptional reliability that caters to both micro and macro-level production.

The technology behind stamping dies consists of advanced techniques that involve Electrical Discharge Machining (EDM) and Computer Numerical Control (CNC) grinding. Such innovations allow for the creation of intricate designs that can meet the demanding specifications of various industries.

Types of Metal Stamping Dies

Metal stamping dies come in several types, each tailored to specific needs. The most common types include:

– Compound Dies: These are designed to perform multiple operations in one motion. They cut and form materials simultaneously, significantly enhancing efficiency.

– Progressive Dies: These involve a sequence of operations across several stages, allowing for continuous material feeding. This type is ideal for high-volume production.

– Fine Blanking Dies: Distinguished by producing precise, burr-free edges, fine blanking dies are excellent for intricate shapes and complex parts.

Each die type serves unique functions and is chosen based on the specific requirements of the application at hand.

Applications in Various Industries

Metal stamping dies are versatile tools that find applications across numerous sectors including automotive, electronics, and industrial manufacturing. In the automotive industry, they are employed to create parts such as brackets, connectors, and battery terminals. The precision required in vehicle components is achieved through the use of metal stamping dies, which ensure consistent quality and performance.

In the electronics sector, these dies help in fabricating components like sensor housings and microelectronic connectors. The rising demand for precise electronic parts has catalyzed the development of custom die designs tailored to unique specifications.

Moreover, metal stamping dies are essential in industrial manufacturing. They are used to produce structural components and metal enclosures, contributing to the assembly of various machines and equipment.

Key Features of Our Precision Dies

Material Options for Versatile Use

Our precision dies are available in a variety of material options, each providing unique traits that are crucial for specific tasks. Commonly utilized materials include:

– SKD11 and DC53: Known for their robustness and wear resistance, these high-carbon tool steels are excellent for producing dies that require dimensional stability.

– ASP23: This high-speed steel variant offers a balance between toughness and wear resistance, making it suitable for high-speed applications.

– Tungsten Carbide: Recognized for its extreme hardness and durability, tungsten carbide is often used in applications demanding long life spans and reduced wear.

Custom-specified alloys can also be utilized for applications that have specific mechanical properties or resistance to chemical attacks.

Advantages of High-Quality Tool Steel

Using high-quality tool steel in the manufacturing of stamping dies confers several significant advantages:

– Durability: High-quality steels have enhanced wear resistance, allowing stamped components to maintain their integrity even under heavy usage.

– Precision: Tool steels enable the production of dies with exceptional accuracy, ensuring that each stamping operation adheres to strict specifications.

– Longevity: Manufacturing dies from premium materials can lead to a lifespan of over one million strokes, depending on the material used and the application, thus providing great value over time.

These benefits collectively contribute to reducing production downtime and improving overall operational efficiency.

Tight Tolerance Control

A cornerstone of our precision dies is the stringent control over tolerances. The standard tolerance for our dies is ±0.005 mm, which can be customized down to ±0.002 mm based on specific customer requirements. This level of precision is critical in industries where slightest deviations in dimensions can lead to functional failures or safety hazards.

All dies undergo rigorous quality checks during production to ensure they meet the required tolerances. Our dedication to maintaining tight tolerances ensures that the components produced are not only reliable but also consistent in performance across extended periods of use.

Advantages of Custom Metal Stamping Dies

Design Support and Customization

One of the most significant advantages of our precision dies is the ability to customize them according to specific design requirements. Our dedicated design team collaborates closely with clients to provide custom die design kits that align with unique production needs. Whether for a microelectronic component or a large structural part, our design support ensures that each solution is tailored to meet the production demands effectively.

Moreover, our engineers offer insights and recommendations throughout the design process. This includes guidance on material selection, feasibility studies, and troubleshooting to achieve optimal outcomes.

Impact on Production Efficiency

Utilizing custom metal stamping dies significantly enhances production efficiency. By optimizing design and material selection, companies can reduce downtime and minimize waste. This streamlined process allows for rapid response to market demands, enabling businesses to adapt quickly without compromising on quality.

The integration of advanced machining technologies, such as CNC and EDM, into the die-making process further ensures that the creation of dies is both efficient and precise, resulting in reduced lead times and consistent results.

Longevity and Reliability

In any production environment, the longevity and reliability of tools are critical. Our precision dies are crafted to endure high-stress applications and maintain performance characteristics over longer periods. The use of quality materials combined with precise engineering means that dies can last through upwards of one million strokes, ensuring that companies can rely on their performance for extensive production runs.

Additionally, the steps we take in heat treatment and surface finishing further enhance the lifespan of our dies, reducing the need for frequent replacements and thereby lowering operational costs.

FAQs About Metal Stamping Dies

What is the typical lifespan of a stamping die?

The lifespan of a stamping die depends on several factors, including the material used, the design, and the application. Generally, our precision dies can last over one million strokes, providing a robust solution for high-volume production requirements. Regular maintenance and proper handling can further extend their lifecycle.

How to request a custom die design?

To request a custom die design, you can contact our design team through our website. Provide your specific requirements, including drawings and materials needed, and our team will collaborate to create a tailored solution that meets your production needs.

What industries benefit from precision dies?

Precision dies are beneficial across various industries, including automotive, electronics, home appliances, and industrial manufacturing. Each sector applies metal stamping dies differently to achieve tailored components that meet unique operational standards.

Conclusion: Elevate Your Production with Precision Dies

Summarizing Key Benefits

Investing in our precision metal stamping dies translates to enhanced precision, longevity, and efficiency within your production process. Our commitment to quality and customization ensures that each die produced aligns with your operational goals while optimizing your manufacturing capabilities.

Exploring Custom Solutions

If your production needs extend to custom applications, our expert design team is ready to assist you in developing tailored solutions. From initial design support to the final product, we are dedicated to providing you with the tools necessary for success.

Contact Us for More Information

For more information about our precision metal stamping dies or to discuss your specific requirements, please do not hesitate to contact us. We are here to provide the expertise and solutions you need to elevate your production standards.