Introduction

High-quality steel projects require accuracy, strength, and dependability at every stage of fabrication. One of the most vital factors in achieving these results is advanced Cutting equipment By using modern cutting equipment, industries can produce precise steel components that meet strict standards. Whether for construction, manufacturing, or custom fabrication, the right cutting equipment ensures projects are delivered on time and with superior quality.

Why Cutting Equipment Is Essential for Steel Projects

Steel projects demand exact dimensions and flawless finishes, which only reliable cutting equipment can provide. Without advanced tools, errors and inconsistencies can compromise structural integrity. High-performing cutting equipment minimizes waste and ensures every cut aligns with design specifications. This reliability makes cutting equipment a key part of delivering high-quality steel products.

Benefits of Advanced Cutting Equipment

The use of advanced cutting equipment offers numerous benefits for steel projects. It allows for faster processing times while maintaining accuracy. Automated cutting equipment also improves safety by reducing manual handling. Additionally, dependable cutting equipment lowers operational costs by minimizing downtime and maximizing material efficiency. These advantages make cutting equipment indispensable in competitive industries.

Cutting Equipment for Different Applications

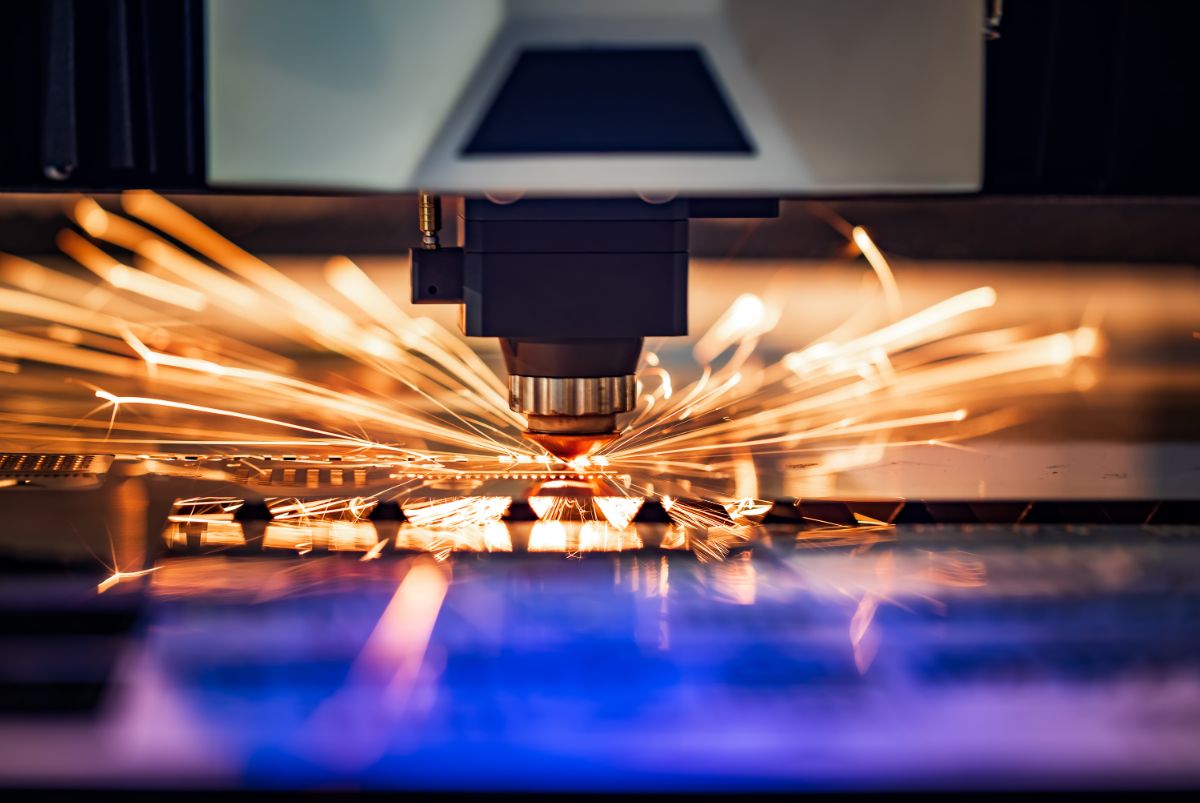

Steel fabrication projects vary widely, requiring different types of cutting equipment. Shearing machines are ideal for straight cuts, while plasma and laser cutters excel at handling complex shapes. CNC-controlled cutting equipment ensures repeatable accuracy for mass production. The versatility of modern cutting equipment allows fabricators to meet diverse project requirements without compromising quality.

How Cutting Equipment Improves Project Accuracy

Precision is at the heart of every steel project, and cutting equipment ensures accuracy with every cut. Automated measurements, laser guidance, and CNC programming allow cutting equipment to deliver consistent results. By reducing errors, reliable cutting equipment helps maintain strict tolerances, ensuring that steel components fit perfectly into larger assemblies.

Efficiency and Productivity with Cutting Equipment

Industries benefit greatly from the efficiency of advanced cutting equipment. Automated systems allow steel processors to complete large projects in less time, boosting productivity without sacrificing quality. Reliable cutting equipment also reduces rework, saving both time and materials. This combination of speed and accuracy makes cutting equipment essential for high-quality steel fabrication.

Industries That Rely on Cutting Equipment

Many industries depend on cutting equipment for their steel projects. Construction, automotive, shipbuilding, and energy sectors all require precise steel components to ensure safety and performance. With advanced cutting equipment, these industries can meet demanding requirements while maintaining efficiency and cost control.

Future Developments in Cutting Equipment

The future of steel projects will continue to rely heavily on evolving cutting equipment. Innovations such as AI-driven automation and predictive maintenance will make cutting equipment even more efficient and reliable. Energy-saving technologies will also help industries reduce costs while meeting sustainability goals.

Conclusion

For high-quality steel projects, advanced cutting equipment is indispensable. It ensures precision, efficiency, and reliability while reducing waste and improving productivity. Across multiple industries, cutting equipment remains the foundation of superior steel fabrication. As technology advances, cutting equipment will continue to drive the success of steel projects by delivering consistent, high-quality results.